Important Safety Considerations While Using Chapati Making Machines

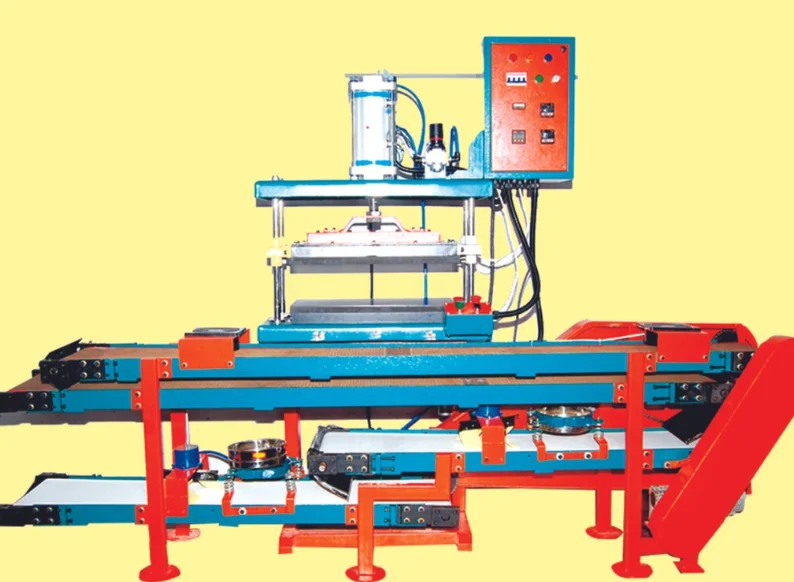

An automatic roti-making machine is a sophisticated piece of equipment designed to streamline the process of roti production. It is a technological innovation that automates various steps involved in making rotis, eliminating the need for manual labor. These machines are commonly used in commercial kitchens, restaurants, and large-scale food production facilities. Depending on the needs of your business, roti-making machines may make partially cooked and completely cooked chapatis. All dough feeding must be done manually. The machine evenly divides the dough into balls of varying sizes, presses, rolls, and cooks the chapatis, thus lowering labor requirements and cooking time. There are various types of automatic chapati-making machines on the market, each with their special characteristics and functionalities: semi-automatic chapati-making machines, semi-cooked chapati-making machines, completely automatic chapati-making machines, and fully cooked chapati-making machines.

Health considerations When Using Chapati Making Machines

When using chapati-making machines, it is essential to prioritize health considerations to ensure food safety and the well-being of consumers. By focusing on ingredient quality and storage, maintaining proper hygiene practices, effectively managing allergens, and ensuring machine maintenance and safety, you can create a healthy and safe environment for chapati production. By adhering to these health considerations, you not only ensure the quality and safety of the chapatis you produce but also promote the trust and satisfaction of your customers.

Hygiene Procedures are essential to follow good hygiene procedures when using chapati-making equipment to avoid foodborne infections. Consider the following:

Operator cleanliness makes sure workers adhere to high hygiene standards, which include frequent handwashing with soap and fresh water both before and during operations. Give them easy access to hand sanitizers.

Machine cleanliness before and after each usage, thoroughly clean and sanitize the machine. Pay close attention to any surfaces, such as rolling pins, conveyor belts, and pressing plates, that come into touch with dough or chapatis.

Equipment and utensils- Throughout the procedure, use sanitized and thoroughly cleaned tools like dough cutters and measuring cups.

Safety Considerations When Using Chapati Making Machines

Chapati-making machines have transformed the process of chapati production, offering speed and efficiency. However, it is crucial to prioritize safety when using these machines to prevent accidents and ensure the well-being of operators.

Operator Training and Instruction

The Safe functioning of chapati manufacturing equipment depends on proper training and familiarization. Operators should get thorough instructions on how to operate the equipment, including knowledge of its numerous parts, controls, and emergency shut-off procedures. Explain to users the possible hazards posed by the device and how to avoid them.

Inspection And Maintenance of Machinery

To guarantee the safe operation of chapati manufacturing equipment, routine maintenance, and inspection are essential. Follow the suggested maintenance plan provided by the manufacturer, and do routine inspections to look for any indications of wear or dysfunction. Pay close attention to the electrical parts, the moving parts, and the safety guards and emergency stop buttons.

Sanitation And Good Hygiene

When utilizing chapati manufacturing equipment, it's essential to practice good hygiene and sanitation procedures to prevent food contamination. Before and after each usage, thoroughly clean the machine to get rid of any leftover food or dough. Sanitize the apparatus using food-grade cleaners, paying specific attention to any locations that come into touch with the dough or the final chapatis

Personal Safety

When operating chapati-making equipment, operator safety is of utmost importance. To prevent burns and other injuries, make sure operators are wearing the proper PPE, such as heat-resistant gloves and aprons. Encourage operators to use safe lifting procedures and to be aware of their surroundings. To avoid strains and injuries, proper workplace design and ergonomics should be taken into account. Implement safety procedures, such as regular breaks to reduce tiredness, and urge operators to report any safety issues or occurrences.

Get Your Best Automatic Chapati Making Machine From JJ Hi Tech Automation

Prioritizing health and safety concerns when operating chapati-making equipment is essential to safeguard operators, uphold hygienic standards, and manufacture high-quality chapatis. The risks associated with operating these devices may be considerably decreased by providing extensive operator training, carrying out routine equipment maintenance and inspections, adhering to good hygiene practices, and putting ergonomic measures in place. Customers who receive machinery from the JJ Hitech Automation company can receive free training. The instruction covers information on how to operate, maintain, and use the machine. So why wait? Get your automatic chapati maker from JJ Hi-Tech Automation & Machineries, a leading manufacturer, producer, and supplier of the best food processing equipment.