How You Can Transform Chapati Production With Commercial Chapati-Making Machines

Chapati, an Indian flatbread, holds a special place in the hearts of millions from many parts of the world. It is a beloved food item in all cultures because of its simplicity, adaptability, and nutritional value. Chapatis were traditionally made manually, with knowledge passed down through the years. But, with the introduction of industrial chapati-making machines, the environment of chapati production is going through an extensive transformation. These innovative technologies are transforming the preparation of chapati and provide many advantages that meet the needs of modern society. This blog post will explore the development of commercial chapati-making equipment and its effects on the food business.

The Traditional Chapati-Making Process

Understanding the conventional procedure is necessary before looking into industrial chapati-making machines. There are various steps involved in making chapatis by hand. Wheat flour, water, and occasionally oil combine to create a soft, malleable dough. The dough is divided into tiny balls and pressed into circular forms. Each ball is manually rolled into thin, even rounds using a rolling pin. The rolled dough puffs up on a hot tava, where the steam causes it to expand. It is set on an open flame to give the chapati its distinctive roasted flavor and texture. It requires skilled labor, time, and effort to achieve this traditional chapati-making process.

Industrial Chapati Making Machines' Development

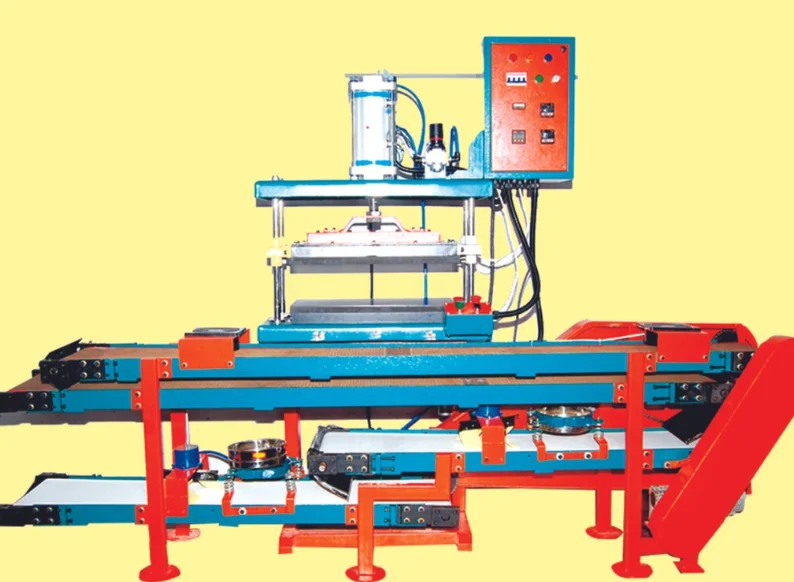

Automation and efficiency contribute to the production of chapatis by industrial chapati-making machines. While drastically lowering the need for user involvement, these machines follow the steps of the conventional process. Automated dough mixing involves combining ingredients and working mechanically to produce a uniform dough. The dough spreads out and is rolled into perfectly round, thin chapatis by the machine, which divides it into equal-sized balls. Chapatis are ready by moving along a conveyor belt and passing through a series of heated plates. It simulates cooking on a tava with a flame, guaranteeing even frying and puffing. It simulates cooking on a tava with a flame, guaranteeing even frying and puffing.

Cleanliness And Quality Assurance

The chapati-making machines dramatically raise the bar for hygienic requirements in industrial food manufacturing. These machines ensure the cleanliness of the cooked food by removing any potential human interaction. This decrease in physical contact ensures that any final product is free from contaminants. When relying only on manual labor, maintaining such a high level of quality control becomes a major challenge. The equipment is a priceless asset in the food sector because it ensures food safety and increases the trust of customers.

Energy Efficiency And Sustainability

Industrial chapati-making equipment offers a more effective use of resources, with sustainability being a main concern. These machines produce a lot of chapatis while minimizing energy use. The automated approach minimizes overcooking or undercooking while maintaining consistent portioning and cooking. The streamlined production method also lessens the need for excessive physical labor with the effective use of human resources. These machines show how technical innovation aligns with sustainability objectives as the globe moves towards an environmentally friendly lifestyle.

Personalization And Flexibility

Chapati-making equipment is available in various sizes and designs to meet varied purposes. There is a machine for every need, from small units appropriate for family kitchens to massive industrial behemoths for large-scale production. This versatility simplifies the cooking process and creates opportunities for creative cooking. Furthermore, having access to many designs encourages experimentation in the kitchen. Chefs can explore various dough varieties, sizes, and even regional variances, broadening the possibilities for culinary inventiveness.

Preserving Tradition

Chapati-making machines represent modernization and convenience while maintaining the integrity of tradition. In reality, they work together to protect ethnic culinary traditions from the effects of time. Even on the busiest days, families may now enjoy the comfort of freshly prepared chapatis. Preserving the rich flavors and methods passed down through the centuries in these machines encourages a sense of continuity and a connection to one's cultural origins. Tradition and innovation reside together in the modern kitchen in this way.

Elevate Your Business with Automatic Chapati Making Machines from JJ Hi-tech, Coimbatore

Chapati-making machines are advancing in sophistication as technology continues to thrive. Future developments for these machines could include integration with intelligent technology, fine control of cooking conditions, and energy-efficient designs. The development of commercial chapati-making machines represents a fundamental change in the method of creating chapatis.

It shows how innovation can balance tradition and modernity while enabling quick access to beloved cultural dishes. These machines help preserve culinary variation and maintain hygienic requirements by saving time and effort. The chapati-making machine from JJ Hi-Tech Automation and Machinery in Coimbatore has established itself as a representation of advancement and practicality. These machines speed up, ensure uniformity, and enable scalability in the process while retaining the flavor and authenticity of this classic cuisine.